OPTIONS IN WHEY SOLIDS RECOVERY

RICOTTA CHEESE LINE

An example of a Ricotta recipe is given below:

100 liters of whey, 10 liters of whole milk, 5 kg of salt. This recipe will approximately yield 4 kg or Ricotta.

Sanchelima International offers you an energy efficient solution regenerating the hot exhausted whey with the warm whey coming from the cheese vat. It goes through heat denaturalization in the specially designed flocculators where the whey protein is separated by acidification. The whey and Ricotta are filtered in a continuous whey draining belt which transports the Ricotta either to waiting molds at the end of the line or to a progressive cavity pump.

DPCS - PARTIAL DEMINERALIZATION AND CONCENTRATION OF WHEY

Equipment: HTST ”Thermoplak” / Centrifugal Separators / DPCS Partial Demineralization of Whey / Evaporator / Crystallizers / HD Dryer.

This will be the next step in solids recovery. This system partially demineralizes and concentrates the whey and prepares it for further uses in products like cultured dairy drinks, ice cream mixes and flavored milk drinks.

Our whey treatment system DPCS provides the following solutions in order to convert liquid whey in to a high quality raw material for other products:

- Enzymes deactivation

- Cheese fines removal

- Fat removal

- Partial removal of mineral salts

- Concentration

- Pasteurization

- Storage

The advantage is to optimize the recovery of the solids by allowing the development of new products or to incorporate them in greater proportion in existing products.

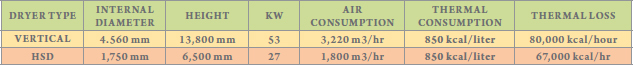

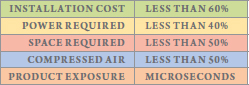

PREASSEMBLED HORIZONTAL SPRAY DRIER HSD

For sure the best way to maximize your revenue is using the whey in products you can get to market and get paid a premium price for a branded liquid product. If this option is not available and you are small to medium size company your want to look at the HSD dryer as it produces an optimum product derived from the short exposure time (microseconds) to dry the whey as opposed to several seconds in tall driers.

The following tables are a comparison and the explanations of the reasons why HSD is a better option in capacities of 770 lbs/hour of dried product and its multiples.

Copyright © 2013 Sanchelima International Inc. All Rights Reserved.