PACKAGING SOLUTIONS

Copyright © 2013 Sanchelima International Inc. All Rights Reserved.

VACUUM AND MAP MODIFIED ATMOSPHERE PACKAGING

The microbial activity and oxidation are the main decaying and degrading processes associated with quality loss of food and dairy products. The protective atmosphere MAP is a very efficient method to delay the bacteriological degradation and rancidity caused by oxidation. We offer you a solution to extend the shelf life of your products with the use of MAP.

Air is composed of 20% oxygen and the concept behind the MAP system is to lower it to less than 2% when performing an inert gas flush and less than 0.5% for vacuum; gas is introduced following the vacuum and before sealing.

The following solutions are available and will be configured according to your specific needs.

- Tray sealing with vacuum and gas flush (MAP)

- Thermoforming for rigid and flexible film with vacuum and gas flush (MAP)

BOTTLE FILLERS FOR LIQUID PRODUCTS

Sanchelima proposes a complete range of semi-automatic and automatic machines dedicated to the dairy industry, on the base of its consolidated experience in bottling and following a constant implementation of technologically advanced solutions. These machines are suitable for the filling of products like milk, yogurt, juices and drinks.

Cleaning is a very important part o the process in order to achieve a longer shelf life. Our fillers are equipped with Ultra Cleaning Electronic System which allows full control of the cleaning cycle without disassembly of the machine. The cycle is optimized to save cleaning products and achieve short cleaning times, reducing the downtime.

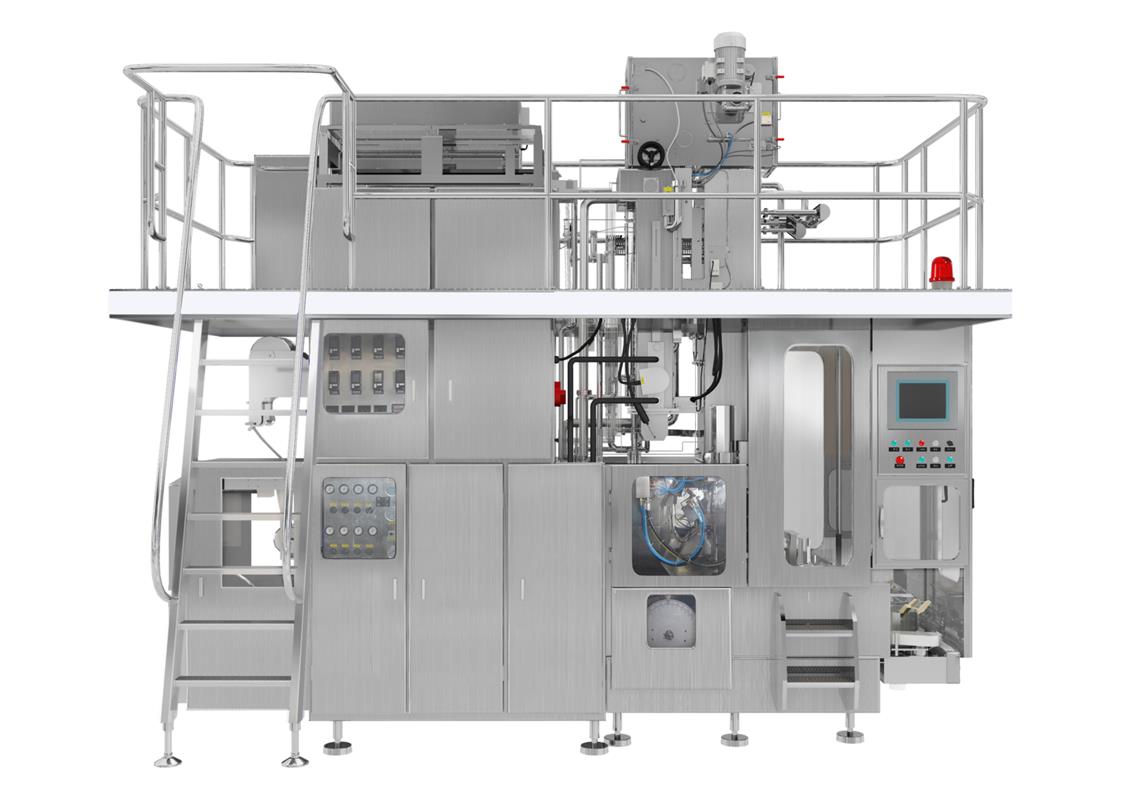

ASEPTIC CARTON FILLER

The machine is ideal for aseptic filling of milk, flavored milk, drinks, juices, wine and other liquid food products.

∙High frequency electrical sealing.

∙Automatic liquid level control for accurate filling.

∙Automatic PP strip application.

∙Rotary discharge plate to avoid accumulation of containers.

∙High quality main components.