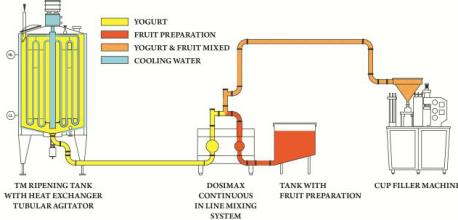

YOGURT PRODUCTION PLANT

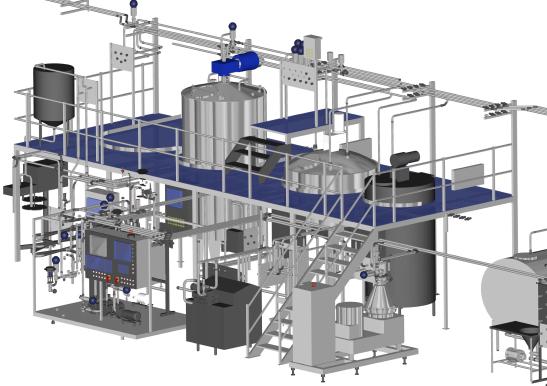

Standardized milk prepared according to the type of yogurt to be produced will arrive from the multipurpose HTST to the TM ripening tank at 80 to 90°C (176 to 194°F) to begin protein denaturalization, the holding time may be from 5 to 20 minutes. The purpose to arrive at this high temperature is to take advantage of the lethal action exerted on the internal wall surfaces of the ripening tank, and then utilize the internal integrated agitator/heat exchanger and the cooling jacket of the TM tank to efficiently cool to ripening temperature. It is also possible to arrive directly at 42-43°C (108-109.5°F) after a 5 to 6 minutes holding time in the Thermoplak HTST if desired.

The objective is to preserve the achieved viscosity created by the acid and other secretion’s coagulation effect of the selected cultures over the ripening time. To achieve this, gentle handling of the yogurt is provided by pumping the product only one time. We achieve this gentle handling and Mixing with our Dosimax, a continuous system designed to texturize and mix the fruit in line at the right proportion through a static mixer.

BENEFITS

- Yogurt maintains its maximum viscosity

- No need to cool the yogurt outside of the ripening tank

- Slow agitator/tubular heat exchanger movement in the TM ripener for uniform cooling

- A uniform pH value is obtained as cooling is programmed according to the acidity curve of the cultures used, allowing prediction of the time needed to start an even cooling of all the product in the tank, as opposed to cooling in a heat exchanger where the first product out will have a different pH compared with the last

- Reduces the costly plant space required

- Reduces initial investment, operation, cleaning and maintenance costs; positive displacement pumps, heat exchangers, mixing tanks, and related CIP, product lines and valves are no longer required

- By using the Dosimax you achieve flexibility to produce different flavors from one batch by simply connecting to a different fruit container

- Accurate dosing of the yogurt and fruit mix by volumetric an infinitely adjustable pumping system

- With our system you simply transfer the product one time directly to the filling machine

YOGURT FILLING SOLUTIONS

A wide range of solutions are available for yogurt packaging. Semi-automatic fillers for low production volumes, automatic rotary filler-cappers for medium capacities, and complete in line filling – capping and packaging modules for larger productions.

Rinsers and HEPA systems are available to preserve the quality of the product by filling and capping under a controlled positive pressure environment.

The main factors to consider in order to select the proper filling equipment are:

- Type; stirred yogurt, drinkable yogurt, set yogurt

- Volume to produce and package per day

- Size, shape and kind of package; bottles, cups, cartons or pouches

- Hygienic level required

Copyright © 2013 Sanchelima International Inc. All Rights Reserved.

In line cup filler 36,000 cups/hour

Rotary bottle non-contact filler with magnetic flow meter system